Another Level of Technology at NCTA

By Dan Stehlik, Ag Mechanics Instructor

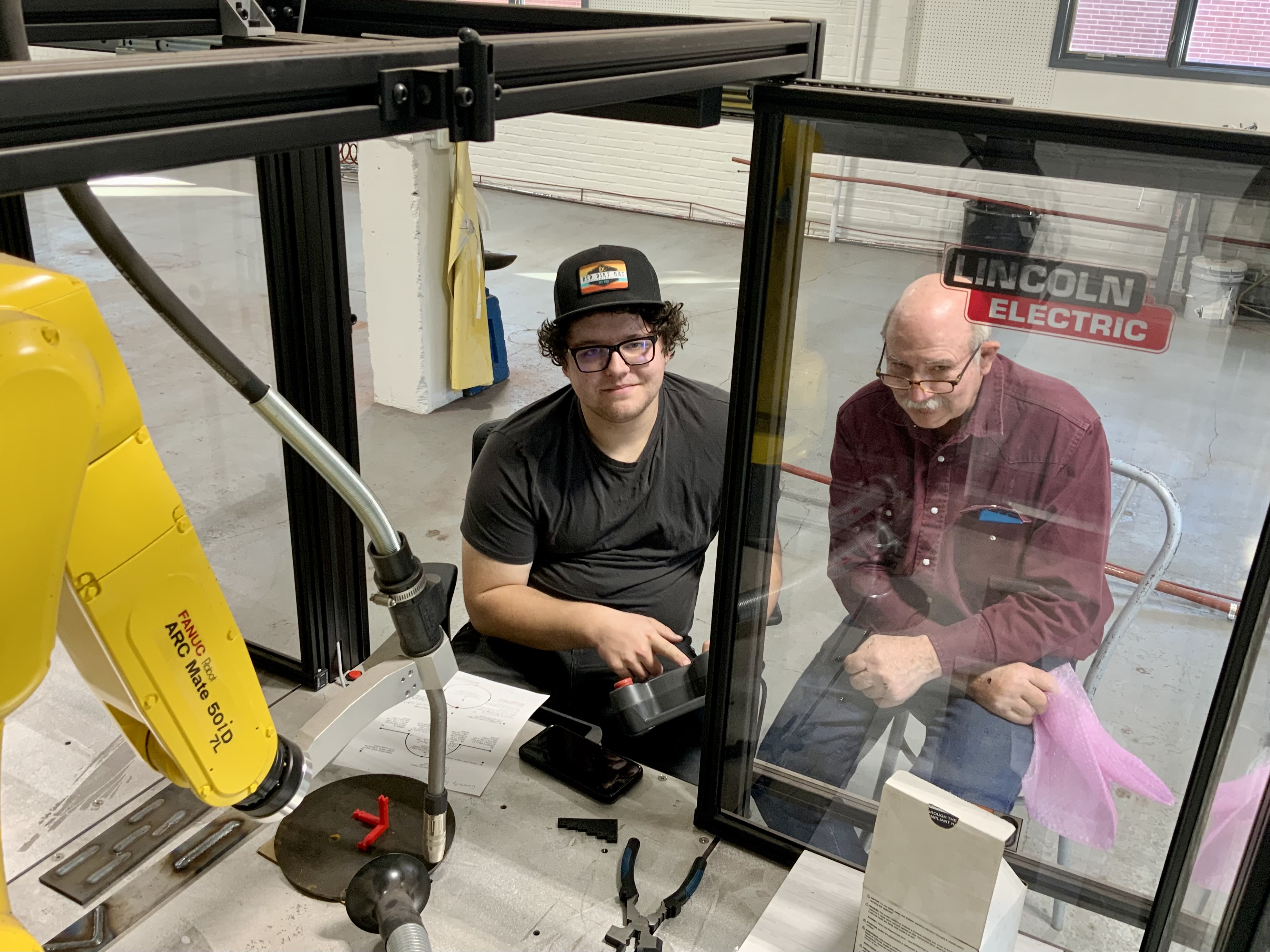

Fourth-semester welding student, Cody Flint has been working the last few weeks with instructor Dan Stehlik to program the robotic welder in the Nebraska College of Technical Agriculture Welding Department. Once the calibrations were re-installed, various movements and welding instructions could be programmed into the Fanuc arm. Cody has set up patterns for the arm to follow a square, to follow a circle, and then to weld the patterns on a plate of steel.

The robot trainer was acquired two years ago through a Federal Perkins reVision Action Grant by the Nebraska Department of Education Office of Career, Technical, and Adult Education written by NCTA dean Larry Gossen. Power to the trainer unit was completed in late 2022. In August of 2023, Stehlik attended a 5-day programming school at the Lincoln Welder plant in Cincinnati, Ohio. Student instruction with the robot unit and other metal technology skills are part of the curriculum for fourth-semester welding students (the Metal Fabrication course).

Automated robotic arm uses in agriculture are becoming more common throughout Nebraska. Examples include Wear Parts of Gothenburg for hard-surfacing sweeps, MetalQuest of Hebron for feeding CNC lathe machines, Reinke Mfg. of Deshler, welding sprinkler fittings onto pipe spans, and others. Two uses in Kansas include Cloud Ceramics of Concordia, removing hot bricks from the kilns, and Stutzman Greenhouses of Yoder, transplanting plant plug trays to 4-inch pot flats.

Additional technologies are continually being added to the many departments at NCTA.

Download a PDF of this press release